This 24V to 36V linear battery charger is long overdue. While this is an old circuit technique, it is optimized for charging higher voltage lead-acid battery packs, and could be used on other types of batteries as well. By proper transformer selection, it can be optimized for either 24 or 36V. Note that actual float charge voltage requires 2.4V /cell or 28.8 & 43.2V @ full charge respectively.

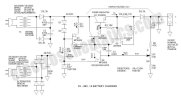

Battery Charger Schematic

Battery Charger Circuit Description

Q1 & Q2 make up a power Darlington using the venerable 2N3055 power transistor. The base of the Darlington is controlled by Q4, the voltage regulator transistor—it compares the feedback voltage coming from the voltage scaling pot with the 6.2V zener reference connected in the emitter circuit. C3 is a compensation capacitor that slows down the regulator in order to prevent potential oscillation.

Instead of using a pull-up resistor to turn the Darlington on, Q3 is configured as a 1mA current source. Working into a current source, Q4 dissipates less power, increases maximum voltage applied to the Darlington and increases voltage regulator gain. High voltage (80V) transistors are required for this application and the MPSA06 and A56 are suggested.

R5 and Q5 make up the current regulator. When the voltage across R5 exceeds about 0.65V, Q5 turns on and shunts base drive from the power Darlington thus causing the output voltage to be reduced. My battery charger circuit ran at 1.1A.

There are two modes of operation—voltage regulation or current regulation—the current regulator (when in operation) takes precedence over the voltage regulator.

Thermal management

I used a puny 5.8°C/W heatsink and while it worked on the bench OK, I recommend a much larger extruded heatsink. I will let you select your own; I did not find an extrusion at DigiKey that was drilled for the TO3 package, so you may have to drill your own heatsink for the 2N3055 transistor. The battery charger circuit has short-circuit protection, but this is momentary at best as the transistor gets very hot. I accidentally shorted the output and yes, the current remained at 1.1A.

Transformer selection

Key to this project is the transformer selection. I started with an old multi-tap Stancor rectifier transformer conservatively rated at 100VA. While this provided the correct DC voltage, I opted to use a smaller 24V transformer that is more representative of what others may have available. Note that the transformer is by far the most expensive item if actually purchased. The BOM indicates an acceptable 24V transformer available at DigiKey. DigiKey does not have an affordable 48V transformer.

To use the 24V transformer, a voltage doubler rectifier is required to obtain the raw 53V supply. Both types of rectifiers are indicated on the battery charger schematic.

Note: to keep the series regulator from having to dissipate an unreasonable amount of power, the raw DC voltage should be about 10V higher than the maximum output voltage. Drop-out voltage is 4.3V—if the raw voltage ever drops below this level, the output drops out of regulation.

Kuberkoos, who suggested this project, will be using a number of transformer secondaries (and/or partial secondaries) connected in series to obtain the required voltage—this also is an acceptable technique.

Getting it up and running

There is much destructive power here so it is wise to bring the voltage up gradually via an adjustable DC power supply or Variac powering the transformer primary. I am glad I did it this way because I had wiring errors that showed up before causing smoke.

What to watch for

When charging a low battery, the regulator will remain in current limit and the voltage will be low until the float charge voltage is reached. At this point, the current will start to decrease.

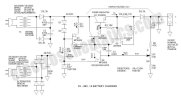

Battery Charger Schematic

Battery Charger Circuit Description

Q1 & Q2 make up a power Darlington using the venerable 2N3055 power transistor. The base of the Darlington is controlled by Q4, the voltage regulator transistor—it compares the feedback voltage coming from the voltage scaling pot with the 6.2V zener reference connected in the emitter circuit. C3 is a compensation capacitor that slows down the regulator in order to prevent potential oscillation.

Instead of using a pull-up resistor to turn the Darlington on, Q3 is configured as a 1mA current source. Working into a current source, Q4 dissipates less power, increases maximum voltage applied to the Darlington and increases voltage regulator gain. High voltage (80V) transistors are required for this application and the MPSA06 and A56 are suggested.

R5 and Q5 make up the current regulator. When the voltage across R5 exceeds about 0.65V, Q5 turns on and shunts base drive from the power Darlington thus causing the output voltage to be reduced. My battery charger circuit ran at 1.1A.

There are two modes of operation—voltage regulation or current regulation—the current regulator (when in operation) takes precedence over the voltage regulator.

Thermal management

I used a puny 5.8°C/W heatsink and while it worked on the bench OK, I recommend a much larger extruded heatsink. I will let you select your own; I did not find an extrusion at DigiKey that was drilled for the TO3 package, so you may have to drill your own heatsink for the 2N3055 transistor. The battery charger circuit has short-circuit protection, but this is momentary at best as the transistor gets very hot. I accidentally shorted the output and yes, the current remained at 1.1A.

Transformer selection

Key to this project is the transformer selection. I started with an old multi-tap Stancor rectifier transformer conservatively rated at 100VA. While this provided the correct DC voltage, I opted to use a smaller 24V transformer that is more representative of what others may have available. Note that the transformer is by far the most expensive item if actually purchased. The BOM indicates an acceptable 24V transformer available at DigiKey. DigiKey does not have an affordable 48V transformer.

To use the 24V transformer, a voltage doubler rectifier is required to obtain the raw 53V supply. Both types of rectifiers are indicated on the battery charger schematic.

Note: to keep the series regulator from having to dissipate an unreasonable amount of power, the raw DC voltage should be about 10V higher than the maximum output voltage. Drop-out voltage is 4.3V—if the raw voltage ever drops below this level, the output drops out of regulation.

Kuberkoos, who suggested this project, will be using a number of transformer secondaries (and/or partial secondaries) connected in series to obtain the required voltage—this also is an acceptable technique.

Getting it up and running

There is much destructive power here so it is wise to bring the voltage up gradually via an adjustable DC power supply or Variac powering the transformer primary. I am glad I did it this way because I had wiring errors that showed up before causing smoke.

What to watch for

When charging a low battery, the regulator will remain in current limit and the voltage will be low until the float charge voltage is reached. At this point, the current will start to decrease.