This is an extension of the earlier 12V SCR Battery Charger.

It is surprisingly easy to increase the output voltage to 24V, but there are both obvious and subtle differences to consider. The most obvious difference is the transition from full-wave center-tapped to a full-wave bridge configuration. In this case, the full-wave bridge is more specifically a semiconverter bridge that contains two rectifiers and two thyristors (silicon controlled rectifiers or SCRs). This project is not recommended for the novice, as advanced trouble-shooting skills and an oscilloscope may be required to get it up and running.

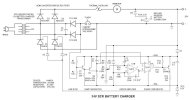

Schematic

Transformer and output voltage

Initially, I thought that the transformer would be a problem, but then I realized that the only thing that had to change is the rectifier configuration. By going from the full-wave center tapped configuration to a full-wave bridge automatically doubles the voltage from 12 to 24V. Of course the output current rating will be lower, but it will be more than half (about 70%) due to the improved secondary waveform that results in lower RMS current. Another consideration is the load regulation, but it is my opinion that it will be satisfactory if it is already designed for battery charger application.

Thermally, the transformer is quite forgiving because its thermal time constant is so long that it can charge at the maximum rate for some time before it gets up to temperature—by that time, the battery terminal voltage has increased sufficiently to reduce the charging current. However, it is a good idea to have a properly rated thermal overload switch—that is what the battery charger manufacturers do and it provides short circuit protection as well, and could prevent a thermal melt-down or fire.

My particular transformer was rated for 3A—any size transformer may be selected provided the power semiconductors have sufficient current rating.

Semiconverter bridge rectifier

A semiconverter bridge consists of (2) SCRs and (2) rectifiers. In this application, the SCRs are located in the lower half of the bridge so that the gates may be driven by a positive current source without the requirement for pulse transformer or optical coupler isolation. I elected to go with discrete TO-220 devices due to low cost, high current rating and availability.

In the BOM, I selected a 25A bridge module. While it is functional, it is intended for reference only because it costs $60. Locating the SCRs in the lower section referred to as “circuit 2.” This is the least common configuration—so uncommon that DigiKey offers only one such module and has only two pieces in stock.

For reference, here are two other module configurations:

“Circuit 1” places the SCRs in the top section—it is the most popular, but cannot be gated via this firing circuit scheme—it usually requires gate isolation pulse transformers.

“Circuit 3” is a full converter that uses four SCRs—full converters are used for regenerative applications rather than simple battery chargers.

Flash function

Because the regulator circuit derives its power from the battery, it cannot charge if the battery is totally dead. For this reason, I added a flash push button and two rectifiers (D11 & 12) these rectifiers are in parallel with the SCRs. In the event the battery is completely dead, this pushbutton may be pressed to manually charge the battery for a few seconds—this should be sufficient to get minimal surface charge into the battery so that it can now power the electronics. In the 12V battery charger write up, I indicated that I thought that the flash function was unnecessary—well, in the course of time, I found it to be necessary.

Note that the pushbutton in this case is quite special, as it must conduct the maximum charge current—most pushbuttons cannot perform this function without damage from either the high current or attempting to interrupt the 24VDC circuit when the pushbutton is released. DC current at this voltage can draw quite an arc and such can be destructive. The Cherry pushbutton indicated in the BOM is rated for 10A @ 28VDC, and is still inexpensive. Also note that rectifiers D11 & 12 are rated for 6A and are overloaded temporarily during the momentary flash function—this is OK because the current is allowed to flow for only a few seconds thus preventing junction over-temperature. For a higher current charger, a series limiting resistor may be required to prevent excessive current.

A secondary use of D11 & 12 is for line voltage synchronization for the phase control circuit.

Circuit Common

Normally circuits use a negative common—that is just the way the world seems to work, but in this case, it was more convenient to make the positive rail the common point—as a result all visualization must be made with this in mind. The only exception is D7 that was installed to prevent damage should the battery get connected reverse. For visualization, simply short out D7. The conventional ground symbol is used for the negative rail.

Op amp selection

Due to circuit common being the positive rail, it was necessary to select an op amp with a common mode range that extends to the positive rail—note that this capability is uncommon among op amps—many op amps like the LM324 /LM358 have a common mode input voltage range that accommodates the negative rail, but these will not work here and neither will the LM741 op amp.

In the earlier 12V version, I recommended the National Semiconductor LF442 op amp, but this device is falling into disuse and the price & availability have subsequently suffered. Instead, I am now recommending the TI TL072 or TL082 JFET input devices—they cost less than $1 each.

One important op amp detail here is powering it via a battery that charges at 29V. While the op amp is rated for 32 volts between rails, the peak voltage of the 24VAC power transformer is dangerously close to that rating. To reduce this voltage, a 6.2V zener diode (D13) is added in series with the negative rail.

Ramp Generator

C1 and R4 form a ramp generator that generates a negative going sawtooth voltage (relative to the positive rail). It is reset to the positive rail via Q1 and Q2 at line voltage zero crossing. At zero crossing, there is no voltage at the anodes of D11 & D12 (relative to the positive rail), Q1 is off, Q2 is on and C1 is shorted. At all other points in the AC line cycle, C1 is charging. My line frequency was 60HZ. For 50HZ, increase the value of R4 to 82K.

Error Amplifier

U1B is the error amplifier—it amplifies the difference between the -6.2V zener diode (reference voltage) and the feedback voltage at the arm of the V ADJ pot (R6). It is slowed down by the RC filter (R10 & C2), proportionately amplified by the ratio of R14 /R9, and integrated via C3. Perhaps you have heard of a PID (proportional, integral, derivative) control—this does just that, but neglects the derivative term as it is generally not required in most applications. If the error amplifier is not satisfied, it continues to integrate its output voltage positive or negative until the feedback voltage equals the reference voltage. The function of the operational amplifier is to make the two input voltages equal.

The device selection here is the LF442 (or TL082) J-FET input operational amplifier. This is vital in this circuit because the common mode voltage range of the differential inputs must extend to the positive rail. Few op amps can do this (many have differential voltages that extend to the negative rail, but those will not work in this application).

Phase Comparator

U1A is the phase comparator. It compares the ramp voltage with the output of the error amplifier. It is also called the ramp-intercept technique. When the ramp generator voltage exceeds the error voltage signal (in the negative direction), the output of U1A switches negative and turns on Q3 thus providing gate current to the SCR that is forward biased. R13 is the gate current limiting resistor. Gate current is approx 100mA.

Because the instantaneous ramp generator voltage is time dependent, the point in time at which the phase comparator output switches is also a function of time. To increase the output voltage (or current), the switching point must advance in phase (relative to line synchronization) in order to apply a greater portion of the half-cycle voltage to the battery.

Reverse polarity protection

If the battery is connected reverse, D7 prevents current from flowing into the regulator circuitry. Since the SCRs cannot be fired, they will not conduct. However, do not press the flash pushbutton—this is a problem that I have not dealt with yet—observe the “Reverse Battery Connection” LED. One potential solution requires the addition of a relay that picks up when the battery is reverse—its contacts open the “Flash” pushbutton circuit.

It is surprisingly easy to increase the output voltage to 24V, but there are both obvious and subtle differences to consider. The most obvious difference is the transition from full-wave center-tapped to a full-wave bridge configuration. In this case, the full-wave bridge is more specifically a semiconverter bridge that contains two rectifiers and two thyristors (silicon controlled rectifiers or SCRs). This project is not recommended for the novice, as advanced trouble-shooting skills and an oscilloscope may be required to get it up and running.

Schematic

Transformer and output voltage

Initially, I thought that the transformer would be a problem, but then I realized that the only thing that had to change is the rectifier configuration. By going from the full-wave center tapped configuration to a full-wave bridge automatically doubles the voltage from 12 to 24V. Of course the output current rating will be lower, but it will be more than half (about 70%) due to the improved secondary waveform that results in lower RMS current. Another consideration is the load regulation, but it is my opinion that it will be satisfactory if it is already designed for battery charger application.

Thermally, the transformer is quite forgiving because its thermal time constant is so long that it can charge at the maximum rate for some time before it gets up to temperature—by that time, the battery terminal voltage has increased sufficiently to reduce the charging current. However, it is a good idea to have a properly rated thermal overload switch—that is what the battery charger manufacturers do and it provides short circuit protection as well, and could prevent a thermal melt-down or fire.

My particular transformer was rated for 3A—any size transformer may be selected provided the power semiconductors have sufficient current rating.

Semiconverter bridge rectifier

A semiconverter bridge consists of (2) SCRs and (2) rectifiers. In this application, the SCRs are located in the lower half of the bridge so that the gates may be driven by a positive current source without the requirement for pulse transformer or optical coupler isolation. I elected to go with discrete TO-220 devices due to low cost, high current rating and availability.

In the BOM, I selected a 25A bridge module. While it is functional, it is intended for reference only because it costs $60. Locating the SCRs in the lower section referred to as “circuit 2.” This is the least common configuration—so uncommon that DigiKey offers only one such module and has only two pieces in stock.

For reference, here are two other module configurations:

“Circuit 1” places the SCRs in the top section—it is the most popular, but cannot be gated via this firing circuit scheme—it usually requires gate isolation pulse transformers.

“Circuit 3” is a full converter that uses four SCRs—full converters are used for regenerative applications rather than simple battery chargers.

Flash function

Because the regulator circuit derives its power from the battery, it cannot charge if the battery is totally dead. For this reason, I added a flash push button and two rectifiers (D11 & 12) these rectifiers are in parallel with the SCRs. In the event the battery is completely dead, this pushbutton may be pressed to manually charge the battery for a few seconds—this should be sufficient to get minimal surface charge into the battery so that it can now power the electronics. In the 12V battery charger write up, I indicated that I thought that the flash function was unnecessary—well, in the course of time, I found it to be necessary.

Note that the pushbutton in this case is quite special, as it must conduct the maximum charge current—most pushbuttons cannot perform this function without damage from either the high current or attempting to interrupt the 24VDC circuit when the pushbutton is released. DC current at this voltage can draw quite an arc and such can be destructive. The Cherry pushbutton indicated in the BOM is rated for 10A @ 28VDC, and is still inexpensive. Also note that rectifiers D11 & 12 are rated for 6A and are overloaded temporarily during the momentary flash function—this is OK because the current is allowed to flow for only a few seconds thus preventing junction over-temperature. For a higher current charger, a series limiting resistor may be required to prevent excessive current.

A secondary use of D11 & 12 is for line voltage synchronization for the phase control circuit.

Circuit Common

Normally circuits use a negative common—that is just the way the world seems to work, but in this case, it was more convenient to make the positive rail the common point—as a result all visualization must be made with this in mind. The only exception is D7 that was installed to prevent damage should the battery get connected reverse. For visualization, simply short out D7. The conventional ground symbol is used for the negative rail.

Op amp selection

Due to circuit common being the positive rail, it was necessary to select an op amp with a common mode range that extends to the positive rail—note that this capability is uncommon among op amps—many op amps like the LM324 /LM358 have a common mode input voltage range that accommodates the negative rail, but these will not work here and neither will the LM741 op amp.

In the earlier 12V version, I recommended the National Semiconductor LF442 op amp, but this device is falling into disuse and the price & availability have subsequently suffered. Instead, I am now recommending the TI TL072 or TL082 JFET input devices—they cost less than $1 each.

One important op amp detail here is powering it via a battery that charges at 29V. While the op amp is rated for 32 volts between rails, the peak voltage of the 24VAC power transformer is dangerously close to that rating. To reduce this voltage, a 6.2V zener diode (D13) is added in series with the negative rail.

Ramp Generator

C1 and R4 form a ramp generator that generates a negative going sawtooth voltage (relative to the positive rail). It is reset to the positive rail via Q1 and Q2 at line voltage zero crossing. At zero crossing, there is no voltage at the anodes of D11 & D12 (relative to the positive rail), Q1 is off, Q2 is on and C1 is shorted. At all other points in the AC line cycle, C1 is charging. My line frequency was 60HZ. For 50HZ, increase the value of R4 to 82K.

Error Amplifier

U1B is the error amplifier—it amplifies the difference between the -6.2V zener diode (reference voltage) and the feedback voltage at the arm of the V ADJ pot (R6). It is slowed down by the RC filter (R10 & C2), proportionately amplified by the ratio of R14 /R9, and integrated via C3. Perhaps you have heard of a PID (proportional, integral, derivative) control—this does just that, but neglects the derivative term as it is generally not required in most applications. If the error amplifier is not satisfied, it continues to integrate its output voltage positive or negative until the feedback voltage equals the reference voltage. The function of the operational amplifier is to make the two input voltages equal.

The device selection here is the LF442 (or TL082) J-FET input operational amplifier. This is vital in this circuit because the common mode voltage range of the differential inputs must extend to the positive rail. Few op amps can do this (many have differential voltages that extend to the negative rail, but those will not work in this application).

Phase Comparator

U1A is the phase comparator. It compares the ramp voltage with the output of the error amplifier. It is also called the ramp-intercept technique. When the ramp generator voltage exceeds the error voltage signal (in the negative direction), the output of U1A switches negative and turns on Q3 thus providing gate current to the SCR that is forward biased. R13 is the gate current limiting resistor. Gate current is approx 100mA.

Because the instantaneous ramp generator voltage is time dependent, the point in time at which the phase comparator output switches is also a function of time. To increase the output voltage (or current), the switching point must advance in phase (relative to line synchronization) in order to apply a greater portion of the half-cycle voltage to the battery.

Reverse polarity protection

If the battery is connected reverse, D7 prevents current from flowing into the regulator circuitry. Since the SCRs cannot be fired, they will not conduct. However, do not press the flash pushbutton—this is a problem that I have not dealt with yet—observe the “Reverse Battery Connection” LED. One potential solution requires the addition of a relay that picks up when the battery is reverse—its contacts open the “Flash” pushbutton circuit.

Eklentiler

Son düzenleme: