| The flyback dc-dc converter topology

results in significant cost and space savings

for multiple output power supplies with high

output voltage for power levels up to 100W.

Flyback topologies store and transfer energy

using a transformer, which due to physical

limitations can cause large voltage transient

spikes during the switching cycle. This article

outlines the design of dissipative voltage

suppression circuits (voltage snubbers) that can

be used to suppress these transients on both the

primary and secondary side.

The flyback topology

(Figure 1A) results in significant cost

and space savings for multiple output power

supplies with high output voltage for power

levels up to 100W. This topology uses a

transformer, which is essentially a coupled

inductor with multiple windings on the same

magnetic core. Flyback topologies operate by

storing energy in the transformer during the

power switch on-time and transferring this

energy to the output during the off-time. The

energy is stored in a non-magnetic gap in series

with the transformer core. In practice, the

multiple windings cannot all be equally well

coupled to the core because of the physical

separation between the windings. A small amount

of energy is also stored within and between

these windings. This energy is represented in

the circuit as a leakage inductance (Figure

1B).

Figure

1A. Basic topology of flyback circuit.

Figure

1B. Equivalent transformer model.

The flyback topology is attractive for

multiple output supplies because the output

voltages track one another with line and load

changes and because adding outputs to the system

does not require additional ICs. Despite its

advantages, the flyback has the disadvantage of

large transient voltage spikes at the drain of

the power switch and at the secondary rectifier.

These spikes are a function of the leakage

inductance in the flyback transformer. Snubbers

control the effects of the leakage inductance

and improve the reliability of the power supply.

Snubbers can be either passive or active

networks. Passive snubber network elements are

restricted to resistors, capacitors, inductors

and diodes. Passive snubbers can control either

voltage or current and may be either dissipative

or non-dissipative. If the energy in the snubber

is dissipated in a resistive element it is

classified as a dissipative snubber, but if the

energy is returned to the input or moved ahead

to the output it is classified as

non-dissipative. This application note provides

an overview of the different types of passive

dissipative voltage snubbers used, guidelines on

how they are designed, and their various

limitations. In particular, snubbers used to

reduce the stress on the switch and improve

efficiency in a flyback topology are discussed.

The first section enumerates the need for a

snubber on the primary side of a flyback

converter. The second section explains the need

for a snubber on the output side. This is

followed by a discussion of the various types of

dissipative voltage snubbers.

Primary Leakage Inductance and the MOSFET

SwitchThe primary leakage inductance

LLP in a flyback does not participate

in the primary to secondary energy transfer and

so has a negative impact on efficiency. Since

the leakage inductance does not find a path for

the current built up in it during the switch

on-time, it leads to a voltage spike at the

turn-off of the MOSFET and also delays the

transfer of power from the primary to the

secondary. The parasitic elements in the

transformer and the switch determine the

magnitude of this voltage spike. At high output

voltagesthe circuit parasitics become large

relative to the amount of output power

delivered.

The primary leakage inductance,

LLP, and the primary winding

capacitance in the transformer, CP,

and the output capacitance, COSS, of

the MOSFET form a parasitic LC network. The peak

voltage is given by:

VPEAK = IP ( (LLP/(CP+COSS)))

+ VIN + VOUT/N (LLP/(CP+COSS)))

+ VIN + VOUT/N

Where IP is the current level

circulating at the time the MOSFET turns OFF, N

is the ratio of secondary to primary turns,

VIN is the input voltage, and

VOUT is the output voltage.

The square root term in the above equation

represents the characteristic impedance of the

parasitic LC network. Note that the highest

voltage transient occurs when switching the

highest level of current. This voltage overshoot

may cause excessive power dissipation in the

MOSFET even if it is within safe operating

limits of the device and thus reduce the total

efficiency. Also, it may cause instability in

the loop due to (dv/dt) induced spurious turn-on

of the MOSFET as a result of the transient

voltage spike.

Secondary Leakage Inductance and the

Rectifier DiodeThe transformer secondary

leakage inductance may couple with the reverse

recovery current IREC of the output

rectifier diode to cause ringing when the diode

turns off. The transformer secondary leakage

inductance LLS and the capacitance

CD of the rectifier determine this

resonant frequency. The ringing may generate

significant radiated and conducted noise. There

is typically very little loss in the resonant

circuit so this network will cause many cycles

of ringing after the spike. The ringing can

therefore affect the current sense signal used

by the controller in a flyback configuration.

The overshoot caused by this ringing may exceed

the diode voltage rating and cause damage to the

diode. The maximum positive voltage across the

rectifier can be estimated as

VPEAK,S = IREC (LLS /CD) +

VIN (LLS /CD) +

VIN  N N

The damping of the resonant circuit should be

optimized as excessive damping can also lead to

increased switching times and result in

increased losses.

A snubber could therefore be used to clamp

the voltage spike or damp the ringing to reduce

noise in the system or both. Depending on the

function performed by the snubber it can be

broadly classified into three categories:

- Rate-of-rise control snubber

- Voltage clamp snubber

- Damping snubber

Damping snubbers are dissipative by

definition. Rate-of-rise control snubbers and

voltage clamp snubbers may be dissipative or

non-dissipative. Non-dissipative snubbers are

generally resonant type snubbers. Snubbers can

also be classified as polarized or non-polarized

depending on whether energy moves in or out of

the snubber at either switching edge or at both.

The polarized snubber is not very good at

damping since it is not active during much of

the cycle. It usually provides rate-of-rise

control or clamping. Depending on whether the

parameter being controlled is voltage or current

these snubbers can be further classified as

voltage or current snubbers. Only dissipative

type voltage snubbers are discussed in this

application note.

RCD Voltage Snubber

This snubber is

applicable to rate-of-rise voltage control

and/or clamping. The presence of the diode in

the configuration makes this a polarized

snubber. The two possible configurations for

this resistor-capacitor-diode (RCD) snubber are

shown in Figure 2. The configuration

shown in Figure 2A can only act as a voltage

clamp. The variation shown in Figure 2B is

applicable to either rate-of-rise control or

clamping of the drain voltage of the switch.

Figure

2A. Voltage clamp snubber.

Figure

2B. Rate-of-rise voltage snubber.

RCD Clamp

In the clamp mode the

purpose of the snubber is to clamp the voltage

during turn-off at the drain of the MOSFET. The

parallel RC circuit may be returned to ground or

to a voltage other than ground (i.e., input

voltage if the drain can go above input voltage)

since this will reduce the power dissipation in

the resistor. The MOSFET switch itself will have

to sustain the peak power dissipation during

turn-off. The value of the capacitor,

CCLAMP, and resistor,

RCLAMP, is based on the energy stored

in the parasitic inductance, as this energy must

be discharged into the RC network during each

cycle. The voltage across the capacitor and

resistor sets the clamp voltage,

VCLAMP. The turn-off waveform at the

drain of the MOSFET switch is as shown in

Figure 3.

Figure

3. MOSFET turn-off waveforms with clamping.

This implies that the power dissipated in the

clamp at turn-off is

PCLAMP = (1/2)  VCLAMP VCLAMP  ICLAMP ICLAMP   t t  f f

Where, f is the switching frequency.

However,

t = (LLP t = (LLP  IP)/(VCLAMP -

VOUT/N).

IP)/(VCLAMP -

VOUT/N).

The power dissipated in the clamp is through

the resistor. Therefore

RCLAMP = [2  VCLAMP VCLAMP  (VCLAMP -

VOUT/N)]/( LLP (VCLAMP -

VOUT/N)]/( LLP  IP2

IP2  f) f)

It is important to minimize the ripple,

Vripple, superimposed on

VCLAMP to keep the MOSFET drain

voltage close to the clamp voltage. The minimum

value for the capacitor, CCLAMP, is

therefore CCLAMP = VCLAMP/

(Vripple  RCLAMP RCLAMP  f). f).

The capacitor, CCLAMP, should have

a low ESR and low inductance to handle the high

peak currents during turn-off. The RC time

constant of the clamp should be chosen much

larger than the switching period of the MOSFET.

The series diode used in the clamp should be

able handle the peak currents and must be a fast

turn-on type.

The RC network may be replaced by a zener

diode that can handle the voltage rating and the

power dissipation. However, since the zener is

not a fast switching device a capacitor may

still be needed in parallel with the zener to

handle the high frequency currents. Note that

this snubber is not used in topologies with a

clamped inductive load since it does not reduce

ringing.

Rate-of-Rise Control RCD

Snubber

When the RCD snubber is used to

control the rate of voltage rise at the MOSFET

drain, the capacitor must be completely charged

and discharged during each cycle to be able to

control the rate-of-rise of the drain voltage.

The RC time constant of the snubber should,

therefore, be much smaller than the switching

period (consider the effect of duty cycle on

pulse width). Typically, the time constant

should be about 1/10th the switching

period. When the switch turns off, the inductor

current is diverted through the snubber diode to

charge the capacitor to the rail. At that time,

it is expected that the output rectifier will

turn on.

When the switch turns on, the snubber

capacitor will discharge through the snubber

resistor and the switch.

The capacitance value is obtained from

IP = C (VC/ tr)

Where VC = voltage across the

capacitor and tr = rise time of the

voltage

The resistor is then chosen based on the time

constant required. The RC time constant is much

smaller than the switching frequency and,

therefore, the power dissipated in the resistor

is independent of its value. The power

dissipation is determined by the value of the

capacitance and the switching frequency. Since

there is only one transition (discharge) through

the resistor, the power dissipation in the

resistor is given by P =

(CVC2f)/2.

Simple RC Snubber

This is probably

the most widely used snubber and is applicable

for both rate-of-rise control and damping. In

inductively clamped topologies, where there is

still some stray inductance, the RC snubber can

be used to reduce the peak power dissipation in

the switch by controlling the rate-of-rise of

drain voltage. The RC snubber, however, will

absorb energy during each voltage transition and

can reduce efficiency. Also, the RC snubber will

reduce the switching speed of the MOSFET switch.

Care must be used in choosing the value of R and

C to optimize the total performance. The main

application of a RC snubber is to damp parasitic

ringing in the circuit due to unclamped

inductance in configurations such as the flyback

converter. In these applications, the value of

the resistor must be close to the characteristic

impedance of the parasitic resonant circuit it

is intended to damp. Choose the snubber resistor

to be

R =  (Lres/Cres) (Lres/Cres)

Where Lres = parasitic inductance

causing the resonance, Cres =

parasitic capacitance causing the resonance.

The RC time constant of the snubber should be

small compared to the switching period but long

compared to the voltage rise time. The snubber

capacitance must be larger than the parasitic

resonance capacitance, but small enough to

minimize dissipation in the snubber resistor.

The snubber capacitance is generally chosen to

be at least 3 to 4 times the value of the

parasitic resonant capacitor. The power

dissipated can be estimated from the snubber

capacitance as

P = C  (VC)2

(VC)2  f f

Where C is the snubber capacitance,

VC is the voltage across the snubber

capacitor, and f is the switching frequency.

It is very important to pay attention to

parasitics in the components used in the snubber

since these may render the snubber ineffective.

The diodes used in snubbers should be able to

handle large peak currents, but the average

current is relatively small. The PC board layout

may need to provide some heat sink area for

these diodes. Capacitors have series inductance

and this should be minimized to avoid

introduction of any unwanted resonance in the

circuit. Some electrostatic capacitors (ceramic

and polymer film) offer extremely low ESR and

ESL values. Capacitors can be paralleled to

reduce circuit inductance. Care must be

exercised in using this method. The series

inductance of a large capacitance is capable of

resonating with a small capacitance in parallel

with it and the resulting resonant circuit will

have a high Q.

The resistors used should have very low

inductance to avoid excessive overshoots and

ringing. Avoid using wirewound resistors. The

layout should not introduce stray inductance,

especially in high current paths. The

transformer used in flyback converters should be

designed to reduce leakage inductance and

minimize overshoot and ringing. The actual

design of the transformer is, however, beyond

the scope of this application note and will be

discussed elsewhere.

The switches in the circuit are usually the

most susceptible devices that need snubbing. The

switch is also in the input stage of the flyback

circuit. In practice, the best procedure is to

start from the input and proceed to the output

stage when introducing the snubbers into the

circuit. Once a node has been shown to need a

snubber, the purpose of the snubber should be

determined before selecting the type.

A flyback topology application circuit using

the MAX1856 is shown in Figure 4. This is

an example of using two snubber circuits for

different objectives. D3, C11 and R11 form a

clamp to limit the drain voltage and R5 with C10

forms a RC snubber to damp the ringing at the

secondary rectifier (D2). Comparing the

waveforms in Figure 5A and Figure

5B demonstrates the effect of the RC snubber

at the secondary rectifier.

Figure

4. Flyback application circuit using the

MAX1856.

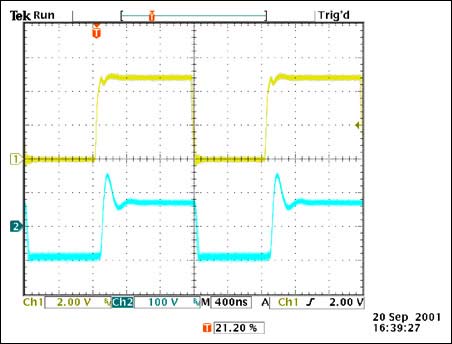

Figure

5A. Voltage at the D2 rectifier cathode without

a snubber. (CH1= Voltage waveform at EXT/pin 8

of MAX1856; CH2= cathode of rectifier D2).

Figure

5B. Voltage at the D2 rectifier cathode with a

snubber (R5=150 ; C10=330 pF). (CH1= Voltage waveform

at EXT/pin 8 of MAX1856; CH2= cathode of

rectifier D2). ; C10=330 pF). (CH1= Voltage waveform

at EXT/pin 8 of MAX1856; CH2= cathode of

rectifier D2).

In conclusion, this application note has

discussed the use of passive voltage snubbers

with particular reference to flyback converter

topology. A properly snubbed circuit is more

efficient, more reliable and will perform well

over time, within temperature and production

tolerances. It is important to understand and

use the snubber circuits when it is necessary to

control switching voltage transients.

We Want Your

Feedback!

Love it? Hate it? Think it

could be better? Or just want to comment?

Please let us know—we act on customer

corrections and suggestions. Rate this page and provide

feedback.

Automatic

Updates

Would you like to be

automatically notified when new application

notes are published in your areas of interest?

Sign

up for EE-Mail.

| More Information |

|

APP 848: Nov 12, 2001

|

|

|

|

Download, PDF

Format (140kB) Download, PDF

Format (140kB)

AN848, AN 848, APP848,

Appnote848, Appnote 848

| |